with particular reference to Turney Brothers leather works, Trent Bridge, 1861-1981

In 1861 two brothers, Edward and John Turney, built a tannery and began to make leather on a site next to the River Trent and the adjacent canal. Turney Brothers, Leather Works, was a landmark on entering or leaving Nottingham for over 100 years. The factory closed in 1981 but the front of the building remains and the land has now been converted into housing accommodation. This year, 2011 would have been their 150th anniversary.

Nottingham has had tanneries in its midst for centuries. In Nottinghamshire Archives there are references to the trade in leather dating back as far as the thirteenth century. An entry in the Records of the Borough of Nottingham in 1395 records the tanners being blamed for polluting the River Leen. The first area the tanners established themselves was in Barker Gate; which derives its name from material used in the trade. Subsequently they moved to Narrow Marsh and there are frequent references in the sixteenth and seventeenth centuries to their yards in this area; within the caves of Nottingham under Broad Marsh shopping centre there is a reference to tanneries. By the seventeenth century Nottingham was a leading centre for the industry with tanneries producing the best upper leather for boots, shoes, harnesses and coverings for coaches and chaises. Tanners were numerous and powerful; 36 in total in 1641, and in 1664 there were no fewer than 47 distinct tan yards. But by 1734 only three tanneries remained and in 1838 the tanning industry had declined to such a state that materials were sold off in the Tanners Hall in Narrow Marsh.

The trade was revived when in 1861 Edward and John Turney purchased a site between the River Trent and the Nottingham canal, known as Sneinton Island, and built a tannery and began making leather. The first buildings only took up a fraction of the space that by the 1920s had developed into a large site with labour-saving machinery imported from many countries.

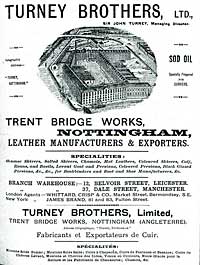

They traded under the name of Turney Brothers and had offices in London, Leicester and Manchester. They set themselves up in producing leather for “fancy leather goods”; for the glove trade, pocket books and other articles, using sheepskins, which they bought from fellmongers with the wool off and in a pickled state. They also sent salted and tanned skins undyed to London and America. This trans-Atlantic trade was able to expand without competition because the Americans had not developed their manufactory as they did later, and after the First World War machinery was imported from America, but it was believed that British manufactured machinery was still far superior. The initial trade in leather laid the foundation for export as a large part of Turney’s output.

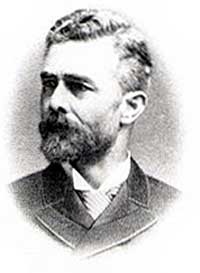

Edward Turney left some years after the commencement of the company and the driving force was John Turney who was in sole charge for over a quarter of a century. He had attended Lincoln Grammar school but between the ages of 12 – 19 years he spent three nights a week at People’s College and the School of Art learning mechanical drawing, which was an advantage to him in running the tannery. In 1888 the company was re-organised into a Limited Company with John Turney as Chairman and Managing Director. Alderman Samuel Herrick Sands and Mr William Goode Johnson were other members of the Board.

Sir John Turney.

John Turney led an exceptionally distinguished social, political and commercial life. He was a member of Nottingham Corporation for 46 years, and became Sheriff and then an Alderman in 1878, and Mayor for two years 1886-8. He was knighted in 1888. For 38 years he was Chairman of the Works and Ways Committee and acted on many other committees involved in improving the borough, working with Arthur Browne, the Borough Civil Engineer. He was a Liberal in politics, leaving the party only over the question of tariff reform. Gladstone was the guest of Turney when he visited Nottingham in 1887. He was a founder member of the Nottingham Rowing Club. In his commercial capacity Sir John was not only Chairman of Turneys but Chairman of the Clifton Colliery Company; Murray Bros. and Co. dyers and bleachers; and the Masonic Hall Company. He was also a Director of the Walsall Glue Company. In 1913 he was made a Freeman of the City of London and in 1915 he was given the Freedom of Nottingham. After the First World War he had a window placed in Gedling Church as a memorial to those who had served their country, at a cost of £1,000. Sir John appears to have had a good working relationship with his work force and there was reciprocal appreciation. He had a brass plate engraved with the names of men from the leatherworks who took part in the Boer war, and the workforce presented him with a congratulatory address thanking him for guiding the firm through the years of 1914-1918 and allowing the company to prosper after the war had finished.

Even so conditions were harsh and anyone found contravening the rules of the factory was instantly dismissed. One former worker who began work at the factory in 1921, recalled working nearly 74 hours in a week and earning £2.19.4d. But as he said, (Sir John) provided a living for many families. When Turneys closed in 1981 most of the workers were middle aged craftsmen who had worked for the company for many years. The majority of workers were male; few women worked in the leather production side. In a document listing the number of under 18 year olds who worked in the factory between 1892 and 1901 they were all male, many only 13 or 14 year olds. Their parents had to certify their age.

Sir John and Lady Turney had a large family, seven sons and two daughters. Sir John Turney died in 1927 and left the firm in the hands of his son John A E Turney and the chairman, Sir Charles Pain.John A E Turney, one of the sons joined the firm briefly before going to the USA. He returned after the 1914-18 war and became Managing Director, where he remained until 1958 when he resigned but stayed on the board.

In 1922 the Nottingham Journal Trade Supplement carried a glowing article on Turney Brothers Ltd, suggesting that the company was now at the cutting edge of the “light leather” trade. The “heavy leather” trade was concerning itself with trunks, straps and belting was mostly to be found in Lancashire. Turneys concentrated on the expanding niche market in leather for motor clothing, hats, uppers leather and lining for the finest boots and shoes as well as their previous fancy goods including purses, pocket books and book binding.

Joseph Turney Wood, photographed in 1924.

One of the reasons for Turney’s success was their interest in advancing the production of leather. In 1866 letters patent were issued to Edward and John Turney granting them sole rights for their improvements in preparing and treating hides and skins for fourteen years. They were fortunate in that a nephew of Sir John, Joseph Turney Wood, had joined the company as an indentured apprentice in 1880, and had devoted a lot of time to the scientific study of leather making and in particular, puering, the obnoxious pre-tanning process whereby dog faeces was used to clean pigmentation and unwanted proteins from the skins prior to tanning. He discovered that it could be done by a new and less unpleasant process with pancreatic enzymes. Wood said of the process, “Puering is not only a filthy and disgusting operation but is prejudicial to health…” Wood was assisted by Douglas Law, who was a very able scientist in the tanning industry and had worked with Professor Procter who was probably the world’s most eminent leather scientist of the time. Wood earned a reputation throughout the trade both at home and abroad, where he had toured extensively visiting tanneries and leather works. In 1922 they had a well-equipped laboratory and staff who carefully examined materials. Processes were controlled and any new inventions were thoroughly examined.

Wood died on 9 June 1924. He had been his President of the Bromley House Library, but was prominent also within the leather and tanning community hence revealed in an obituaries in the Journal of the American Leather Association, (January 1925), The Leather Trades Review, (10 November 1926), as well as memorial addresses in 1926 in Turin and Paris.

During the Great War output expanded, when most of the production went over to the manufacture of army clothing. Turneys were fortunate that in this period when dye plants were normally diverted to munitions production, they had stocks which they could use and sought ways around the shortages.

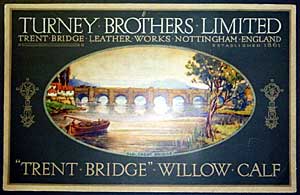

With the USA now an important leather producer Turneys had to keep one step ahead of their competitors and they were able to do this in two ways; they equipped themselves with labour-saving devices which the 500 staff used very efficiently. Secondly, the premises were constantly being extended throughout the twenties and thirties to keep up with the increasing market. For the first fifty years of the company the main process was splitting and tanning sheepskins. These were purchased from places as far a field as Jedburgh, Burnley and Pontefract and closer to home from Grantham; experienced members of Turneys made frequent trips around Great Britain to buy the pelts. During the Great War sheep skins, goat skins and calf skins were constantly being delivered to the premises. By 1922 New Zealand lamb skins were being used. The art of splitting leather had long been established at Turneys; the upper was used for fancy leather and lower was used for chamois leather. With the increase in machinery the production moved to full chrome calf leathers known as “Willow Calf” (because of its softness and flexibility) which attained a growing reputation for quality and was produced in many colours for the ladies’ shoe trade.

The company opened warehouses in Leicester and Northampton to deal with the supply of upper leathers to the shoe trade at source. At the onset of the Second World War, a much heavier type of leather was required for the production of army boots. This was feasible because the light calf skin manufacture had been superseded by medium weight ox hides and traded under the name of “Levant”, and produced leather for the highest grade shoes. Although the production of full-chrome shoe leather had increased, the original sheepskin production on which the business had started continued to flourish. With the introduction of resin finishes, sheepskin could be made into grain clothing, and this together with the popular suede clothing was produced in bulk and created a large export market to the Continent. In order to continually promote their products Turneys exhibited at prestigious fairs such as the Earls Court Leather fair and the “Semaine de Cuir” in Paris.

The company celebrated its centenary in 1961; the chairman and managing director at this time was Cyril Herrod who had joined the company in 1917. The company continued to be a major manufacturer in Nottingham but was taken over by the Booth Group in 1971. Booth’s also had a 50% share in Wade and Company (1901), previously known as Whitemoor Leather Works, the only other sizeable tannery in Nottingham. Booth’s had bought 100% of Wades on the death of Charles Wade in 1956. Wades closed in 1980.

Turney Brothers was closed in 1981 the only remaining tannery in Nottingham, as Wades had closed in 1980. According to the official accounts they had made severe losses over the previous three years and despite redundancies the company was no longer viable. The managing director at the time, Michael Redwood blamed the increased price of raw materials and the lack of demand for shoe leather, as well as the general depression and problems in the UK shoe and leather market.

Turney Brothers, was for many years a leading manufacturer in Nottingham. It may not have been as prestigious as Boots, Players or Raleigh but in its sphere it was at the cutting edge of leather production and their name was synonymous with high grade leather production both at home and abroad.